Now more and more people are joining the team of shit shoveling officers, and the styles of cat cans are becoming more and more abundant, such as tin cans and soft cans. Among them, the full name of "soft cans" is soft packaging cans, which were developed for astronauts at the earliest stage. It is the second innovation in the history of food packaging, which is equivalent to the difference between new energy vehicles and fuel vehicles. Where is it new? The most critical new material is the packaging material of soft cans is a composite plastic film bag. Don't underestimate this simple change. Compared with bottles and barrels of the same capacity, the consumption of packaging raw materials is reduced by more than 30%, the cost of storage and transportation of packaging materials is reduced by more than 60%, and the amount of waste disposal is reduced by more than 5 times. It is a new can packaging solution that combines light weight, small size, easy opening, storage resistance, higher space utilization, and lower transportation costs!

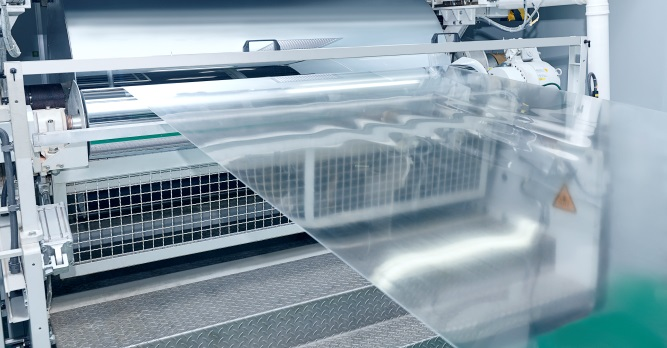

"Soft cans" need to meet the requirements of transportation and food shelf life while achieving lightweight packaging. This requires that the raw materials for making flexible packaging must have the characteristics of high strength and high barrier, and PA6 is the "chosen child". Sinolong focuses on the R&D, production and sales of high-performance PA6 slices. It is one of the main raw material suppliers of high-quality functional membranes in China. SC28 or SM33 represents film-grade PA6 slices, which can be processed into functional films by biaxial stretching, casting and other methods. The film has high thermal stability, good transparency and gloss, excellent toughness and puncture resistance and excellent gas barrier properties. Most packaging manufacturers choose high-quality and high-barrier flexible packaging raw materials, which can not only reduce their own packaging consumables and transportation costs, respond to the demand for lightweight, but also improve consumer experience. At present, Sionlong Film grade PA6 chips have become the best choice for flexible packaging materials such as food, medicine and daily chemical products.

The contribution of PA6 slices to lightweight is not only in flexible packaging, but also plays an important role in the field of mass transportation. For example, engineering plastic grade PA6 slices represented by Sinolong’s SC24 are a powerful driving force for lightweight vehicles .

According to the research of China Tramway Network, every time a new energy vehicle increases its battery life by 1 kilometer, it needs to increase the weight of the battery by 1KG, and every time the vehicle loses 100KG, the battery life will increase by 6%-11%. In terms of parts and components, the weight of automobiles has been improved, and new energy vehicles have also ushered in a "slimming wave". Sinlong has a wide range of products and stable quality. The engineering plastic grade PA6 chip can meet the diverse needs of modification processing applications. It is widely used in automotive related parts. While ensuring strength and safety performance, it can be Realize the "open source and reduce expenditure" in the quality of the whole vehicle, so that more weight can be allocated to the power battery, effectively improving the battery life of new energy vehicles. Tesla Model 3 is a beneficiary of the lightweight solution. It uses plastics to reduce the weight of electrical parts and structures, reducing the weight of the vehicle by more than 67 kg!

With the progress of society and the development of science and technology, lightweight has become the development consensus of many industries. Whether it is a shit shovel officer or Tesla, they are both followers and beneficiaries of the application of lightweight materials. Relying on Quanhui's unique location advantages, Sinolong has a well-connected logistics network, and continues to radiate high-quality and diverse PA6 chip products to the global functional film and engineering plastics industry clusters. Lightweight empowerment of similar commodities.

Post time: Jul-14-2023