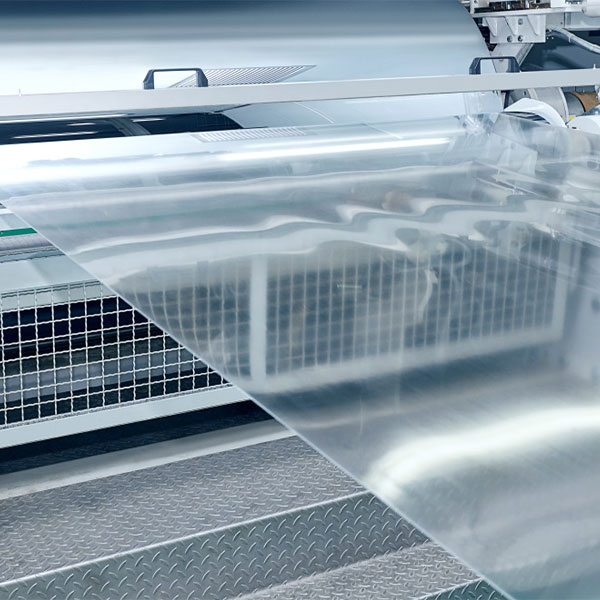

Film Grade Polyamide Resin For High-Quality Film Applications

Product Detail

High-performance film grade polyamide resin

Film grade virgin nylon6 chips with high transparency, good strength and excellent processing performance.

Film-grade polyamide6 resin can be processed into polyamide film by biaxial stretching, multi-layer co-extrusion and other ways. Polyamide film made from our film-grade PA6 chips has high mechanical strength, high thermal stability and excellent gas barrier characteristics, it is widely used in producing food vacuum packaging, pharmaceutical packaging, daily chemical product packaging and express packaging, such as common beef packaging, ham packaging, cheese packaging, needle packaging, daily necessities packaging, air column bags, etc. These terminal products are benefiting from the excellent characteristics of film-grade nylon6 resin.

Product features: stable viscosity, stable molecular weight distribution, good strength, high transparency and excellent processing performance

Product features: stable viscosity, stable molecular weight distribution, good strength, high transparency and excellent processing performance

Quality control:

Quality control:

| Application | Quality control index | Unit | values |

| Film grade PA6 resin | Relative viscosity* | M1±0.07 | |

| Moisture content | % | ≤0.06 | |

| Hot Water Extractable | % | ≤0.5 |

Remark:

*:(25℃, 96% H2SO4,m:v=1:100)

M₁:Relative viscosity center value

Product application

Biaxial oriented film

Through melt extrusion, casting, and then longitudinal, transverse ( or simultaneous ) stretching, a biaxial stretching film is made. BOPA film has good transparency and glossiness, excellent toughness and puncture resistance, excellent gas and odor barrier, and good printing performance. It is widely used in the packaging of cooked food, frozen food, ordinary food, daily chemicals, medical supplies, machinery, electronic products and other products.

Coextrusion film

Through the multilayer co-extrusion technology, different properties of the base material are compounded, which can comprehensively utilize the properties of various base materials. Among them, polyamide have good barrier properties and mechanical properties, which can meet the different design requirements of flexible packaging. Because of its good barrier properties, strong functions and flexible structural design, nylon film widely used in meat packaging, food packaging, air column bag, medical packaging and other products.

FAQ

Please kindly note:

Sinolong is mainly engaged in the R&D, production and sales of polyamide resin, products include BOPA PA6 resin, co-extrusion PA6 resin, high-speed spinning PA6 resin, industrial silk PA6 resin, engineering plastic PA6 resin, co-PA6 resin, high temperature polyamide PPA resin and other series of products. The products have wide range of viscosity, stable molecular weight distribution, excellent mechanical properties and good processing performance. They are widely used in BOPA film, nylon co-extrusion film, civil spinning, industrial spinning, fishing net, high-end fishing line, automobile, electronic and electrical fields. Among them, the production and marketing scale of film-grade high-performance polyamide materials is in word leading position. High-performance film grade polyamide resin.