Under the strict regulation of Covid, the Service to Home Economy is popular everywhere. By 2022, the quantity of express in China has been at top one over three years. Meanwhile, cross-border e-commerce has beendeveloping faster and faster in markets of EU, US and Southeast countries. On the one hand, consumers gradually become more rational, and pay more attention to quality and health in choosing goods. On the other hand, from goods production to packaging, from purchasing to express delivery, the concept of green environmental protection is applying to every consumption chain.

According to the data of the National Post Office of China, China's express volume exceeded 100 billion pieces in 2022, and hundreds of millions of discarded express packages were produced every day, it had resulted in increasingly serious environmental pollution and waste of resources. The traditional cushioning packaging materials for express, such as foam and pearl cotton, have caused serious pollution due to the difficulty in recycling, which has greatly restricted the development of the express packaging industry. With the development of technology, the cushioning air bag came into being as a new packaging solution. It is made of environment-friendly and non-toxic PA/PE co-extruded plastic film. It uses the air cushioning function, and has the characteristics of recyclability, extrusion resistance, abrasion resistance, puncture resistance, etc. It is an ideal green material to replace the traditional express packaging.

At the same time, the cushioning air bag is deeply trusted and provides transportation safety guarantee for consumers to buy goods online. More and more consumers are used to buying valuable goods online such as wine, cosmetics, electronic products, etc. They are usually delicate and are easily damaged by collision and extrusion. The cushioning gas bag perfectly solves this problem. It plays a protective role in the face of various impacts, vibration, friction, extrusion during transportation.

Why is the small cushioning air bag so powerful? The secret is that it uses a special material which is film-grade polyamide. This is also the reason why it has better comprehensive performance than traditional packaging materials. The safety index of the cushioning gas bag is positively related to the content of film-grade polyamide, which is the higher content of polyamide in the cushioning air bag, the better its puncture resistance and protection performance it is. Especially when it is squeezed, the better of elongation ability in the co-extruded film, the bigger impact force it can bear during transportation.

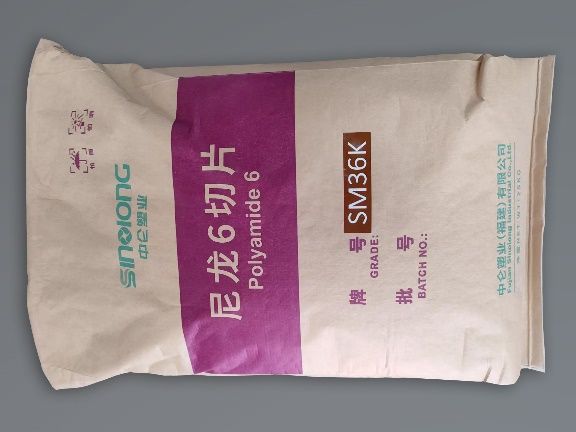

The rapid popularization of cushioning air bags in the field of express logistics is highly related to the fast development of the upstream material industry. In the field of film-grade polyamide, as a leading expert in high-performance polymer industry, Fujian Sinolong Industrial Co., Ltd. provides high-quality, stable and sufficient raw material for cushioning air bags production.

Relying on the leading polymerization technology, the film-grade polyamide independently developed and produced by Sinolong has the characteristics of stable viscosity, stable molecular weight distribution, good strength, and excellent processing performance, which is the key to strengthen cushioning air bag with strong functions. It mainly reflects in three aspects, firstly, high strength and high toughness, significantly improving the safety performance of the cushioning air bag, and easily coping with collision and extrusion in transportation. Secondly, it has high barrier and good puncture resistance, ensuring the protection function, and effectively preventing the occurrences of damage caused by air leakage and touching sharp objects. Thirdly, raw materials are safe, environmentally friendly, pollution-free, recyclable, and meet the EU ROHS green environmental protection requirements, providing a solution for the difficulty of recycling traditional express packaging.

The green innovation of express packaging materials represented by cushioning air bags marked that the rapid development of e-commerce evolves to high-quality development. Nowadays, more and more green and functional new materials are applied to e-commerce logistics. From carbon reduction to health and safety, from energy saving to intelligent efficiency, material technology innovation has become an important force to promote the high-quality development in e-commerce industry.

Post time: Feb-27-2023